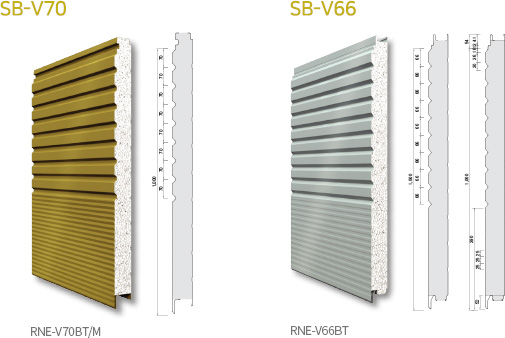

ZB ZINC EXWALL PANEL

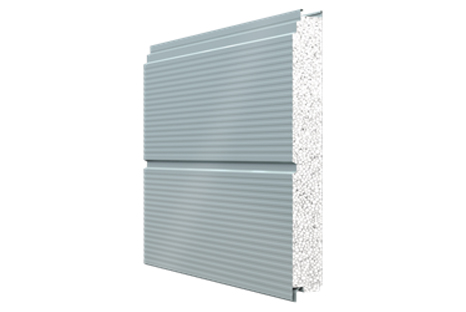

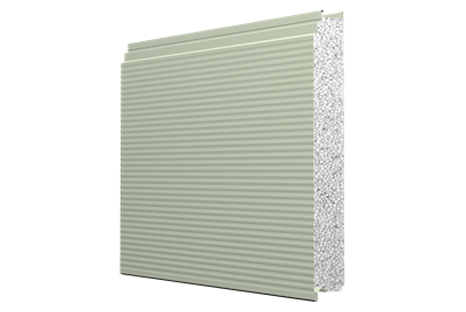

Sandwich Panel is used in construction with 2 corrugated galvanized iron sheet adhered with insulation in the middle, not only brings an eye-catching appearance but also helps against heat for the project effectively; In addition, the construction is very convenient, easy and shortens the construction time.

Panel is one of the most widely used materials, also known as styrofoam, using a polystyrene-stimulating insulation. Not only does it have outstanding thermal insulation properties, but it also has outstanding rigidity due to its high density of polystyrene expansion, so the panel is now widely used.

|

Product specifications |

Items |

Specifications |

|

Upper and lower surface layer |

0.45 ~ 0.6mm corrugated galvanized iron sheet is coated with polyester, silicone or PVDF |

|

|

The insulation core in the middle |

Normal EPS |

|

|

Standard size |

1000 mm |

|

|

Length |

2 ~ 7m (can order longer than 7m) |

|

|

Thickness |

50mm, 75mm, 100mm, 125mm, 180mm, |

|

|

*Specifications may be adjusted according to actual order size |

||

|

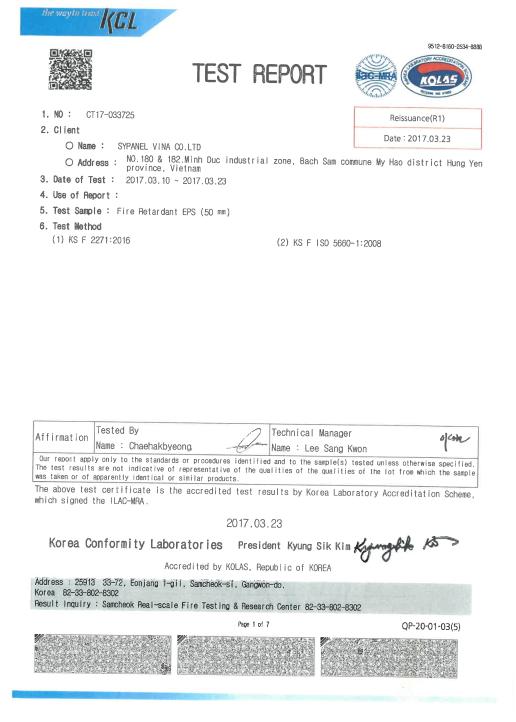

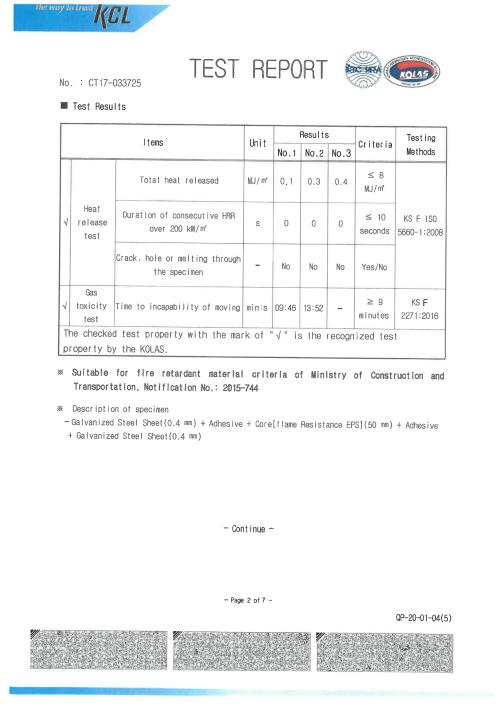

Fire safety |

The panel manufacturing method is recognized as being fire resistant and flame retardant. |

|

Economy and construction ability |

Simple and standardized panel assembly method saves time and construction cost |

|

Lightweight and durable |

The hardness of the Panel depends on the density of the EPS, this easily calculates the load and is convenient for construction |

|

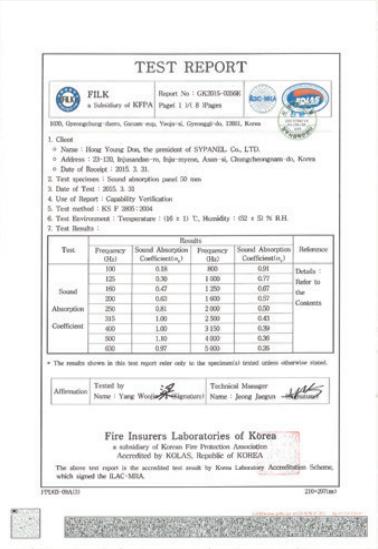

Insulation capacity |

The insulation capacity is 21.5 times higher than that of fired bricks, 49 times higher than that of concrete |

Fire test report

Fire test report

Soundproof Test Report