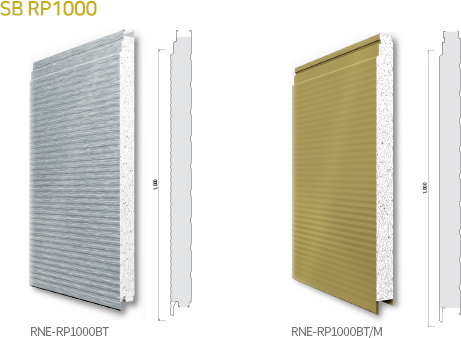

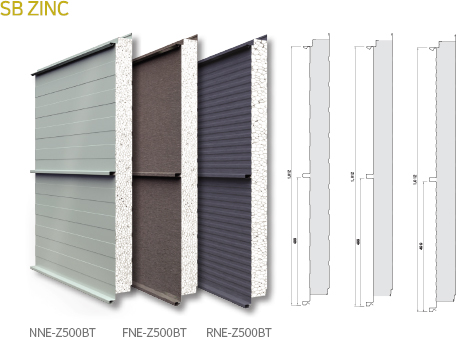

ZB ZINC EXWALL PANEL

Sandwich Panel is used in construction with 2 corrugated galvanized iron sheet adhered with insulation in the middle, not only brings an eye-catching appearance but also helps against heat for the project effectively; In addition, the construction is very convenient, easy and shortens the construction time.

Panel is one of the most widely used materials, also known as styrofoam, using a polystyrene-stimulating insulation. Not only does it have outstanding thermal insulatio n properties, but it also has outstanding rigidity due to its high density of polystyrene expansion, so the panel is now widely used.

n properties, but it also has outstanding rigidity due to its high density of polystyrene expansion, so the panel is now widely used.

|

Product specifications |

Items |

Specifications |

|

Upper and lower surface layer |

0.45 ~ 0.6mm corrugated galvanized iron sheet is coated with polyester, silicone or PVDF |

|

|

The insulation core in the middle |

Retardant EPS |

|

|

Standard size |

1000 mm |

|

|

Length |

2 ~ 7m (can order longer than 7m) |

|

|

Thickness |

50mm, 75mm, 100mm, 125mm, 180mm, |

|

|

*Specifications may be adjusted according to actual order size |

||

|

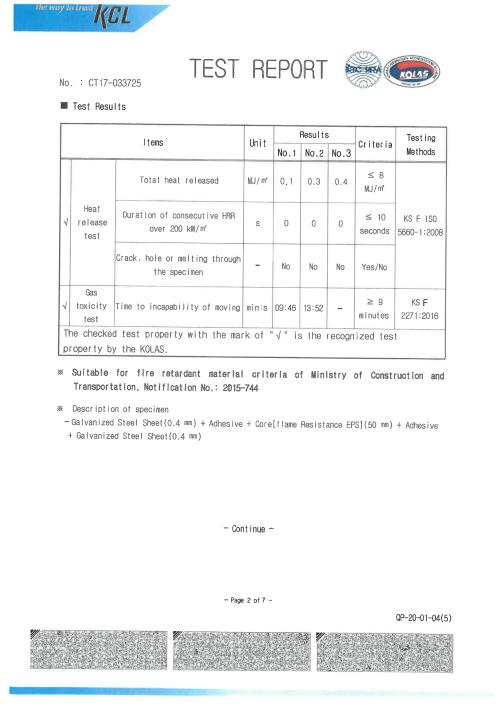

Fire safety |

The panel manufacturing method is recognized as being fire resistant and flame retardant. |

|

Economy and construction ability |

Simple and standardized panel assembly method saves time and construction cost |

|

Lightweight and durable |

The hardness of the Panel depends on the density of the EPS, this easily calculates the load and is convenient for construction |

|

Insulation capacity |

The insulation capacity is 21.5 times higher than that of fired bricks, 49 times higher than that of concrete |

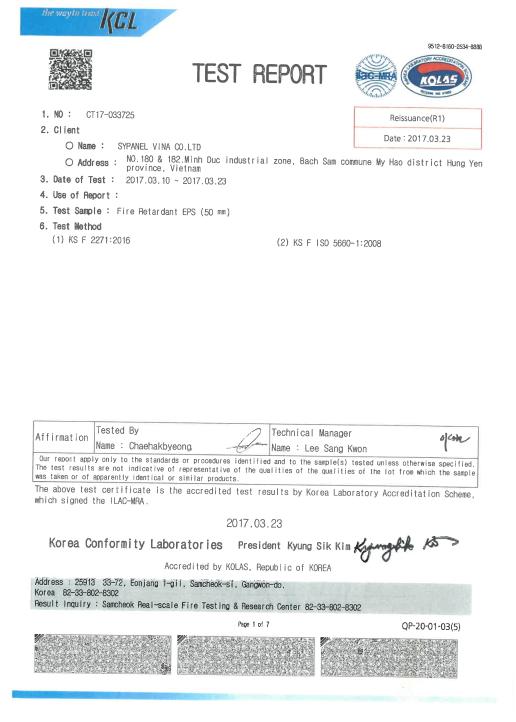

Fire test report

Fire test report

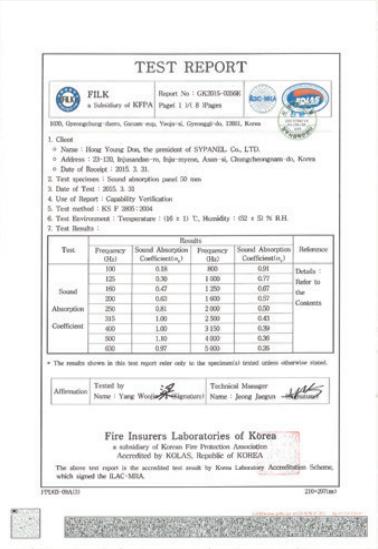

Soundproof Test Report